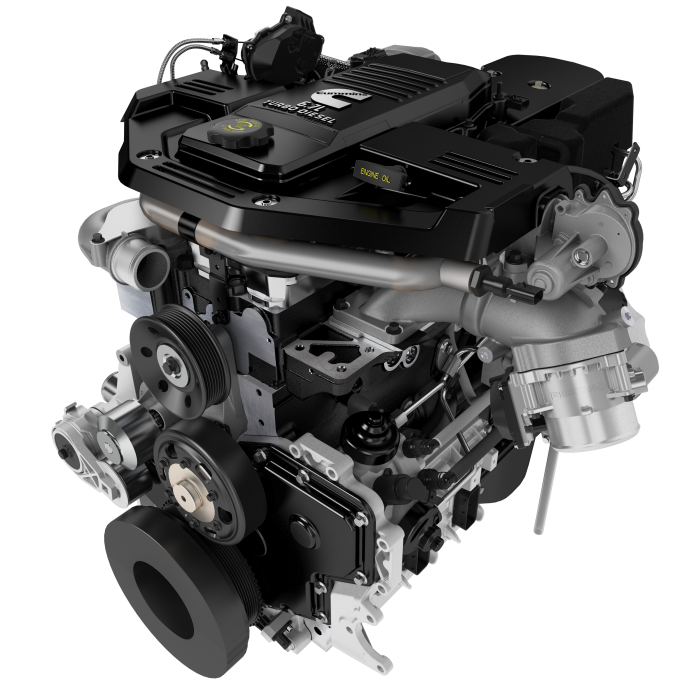

CUMMINS ENGINE

There are three significant hitters in the light-duty diesel world. Two makes offer V8 turbo diesel configurations, and the other make comes to play with an inline 6. Don’t discount this engine missing two cylinders alongside its competitors. It is comparable in cubes, and as historic data shows, inline engine configurations effortlessly outperform V8 counterparts. Halfway through 2007 the 6.7 liter, inline 6 Cummins engine emerged and came out swinging against its competitors. Continuing Cummins’ legacy from the infamous 5.9 liter everyone crazes over, the 6.7 offered much more useable tech for the engine.